JANUARY 16, 2024

1000 Kelvin and Fieldmade to Support Military with “First-time Right” Field-Deployed 3D Printing

Tampa, FL [January 16, 2024]—At the Military Additive Manufacturing (MilAM) Summit & Technology Showcase, 1000 Kelvin, a US and Germany based AI-driven additive manufacturing (AM) software company, and Fieldmade, a Norwegian pioneer in mobile manufacturing for rugged environments, announced a significant partnership set to rapidly increase the immediate deployment of 3D printing at the front lines, enhancing strategic readiness and operational capabilities within the military sector.

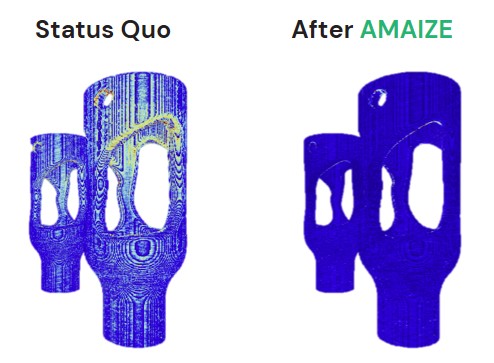

1000 Kelvin's innovative AMAIZE platform, utilizes artificial intelligence (AI) informed by physics and manufacturing data to provide AM engineers with an AI-copilot, correcting print recipes and ensuring successful production of AM parts on the first try. This technology aligns seamlessly with Fieldmade's expertise in creating deployable AM solutions, such as their NOMAD® Series of transportable AM modules. By combining their products, the two companies enable users in fields of battle to immediately begin producing parts as soon as their 3D printer modules arrive on site, ensuring swift adaptability to operational needs.

1000 Kelvin’s software acts an AI-copilot for 3D printing. By using a physics-informed AI, AMAIZE automatically identifies and corrects issues in a print file without altering the original design to achieve a perfect part the first time it is printed.

According to Jostein Olsen, CEO of Fieldmade, "Our vision is to make deployable 3D printing as easy as using a vending machine. The integration of 1000 Kelvin's AMAIZE into our products is a significant step towards this goal."

With a history of collaborating with the Norwegian Armed Forces and other defense entities, Fieldmade is an ideal partner for 1000 Kelvin, which has already seen its software integrated into production level metal 3D printers. Fieldmade’s ability to deploy units capable of operating in diverse conditions complements 1000 Kelvin's goal of enhancing AM's efficiency and accelerate engineering.

Fieldmade creates deployable AM solutions, such as the NOMAD® Series of transportable AM modules, collaborating with the Norwegian Armed Forces and other defense entities.

Fieldmade creates deployable AM solutions, such as the NOMAD® Series of transportable AM modules, collaborating with the Norwegian Armed Forces and other defense entities.

Omar Fergani, Ph.D., CEO and co-founder of 1000 Kelvin, highlights the potential impact of this partnership, "By combining our strengths, we're not just advancing technology; we're providing solutions that can save time, costs, and in critical military scenarios, even lives."

The collaboration between 1000 Kelvin and Fieldmade sets a new standard in AM, particularly for the military sector, by offering end-to-end additive solutions that ensure high-quality part production rapidly, anywhere and anytime.

About 1000 Kelvin

1000 Kelvin helps additive manufacturers reduce the time and cost of printing high quality metal parts. The company’s AMAIZE software is the “AI copilot” for engineers, predicting print issues upfront, performing corrections, and generating industrial-grade, ready-to-use print files specific to a machine. AMAIZE uses machine learning models to predict print challenges and correct them directly in the print file, increasing the number of prints that are perfect on the first try.

About Fieldmade

Fieldmade, a spin-off from the Norwegian Defence Research Establishment, is a leader in on-site manufacturing and on-site repair of replacement parts. Using its NOMAD Micro Factory series, Fieldmade employs advanced additive manufacturing technology directly at the point of need. Since its founding in 2016, Fieldmade has grown into the technology leader for deployable Laser Powder Bed Fusion (L-PBF) micro factories. Its technology has been successfully demonstrated in several field exercises and commercial deployments in the Energy sector.