Increase your additive manufacturing productivity

Enhance your workflow with tools to analysis printability, cost estimation, automatic build preparation, and exposure strategy optimization. Minimize risks, reduce costs, and improve production quality effortlessly.

Increasing your additive manufacturing productivity

Achieving success in laser powder bed fusion (LPBF) metal 3D printing demands precision and efficiency—balancing cost control with consistent, high-quality output. AMAIZE from 1000 Kelvin transforms your workflow with its cutting-edge AI capabilities, offering automated printability checks to validate designs, physics-driven AI for optimized build preparation, and smart adjustments to scan strategies and process parameters. By addressing potential issues before printing even begins, AMAIZE ensures first-time-right results, streamlining the entire production process from data preparation to post-processing for reliable, cost-effective performance.

Our Advanced Tools

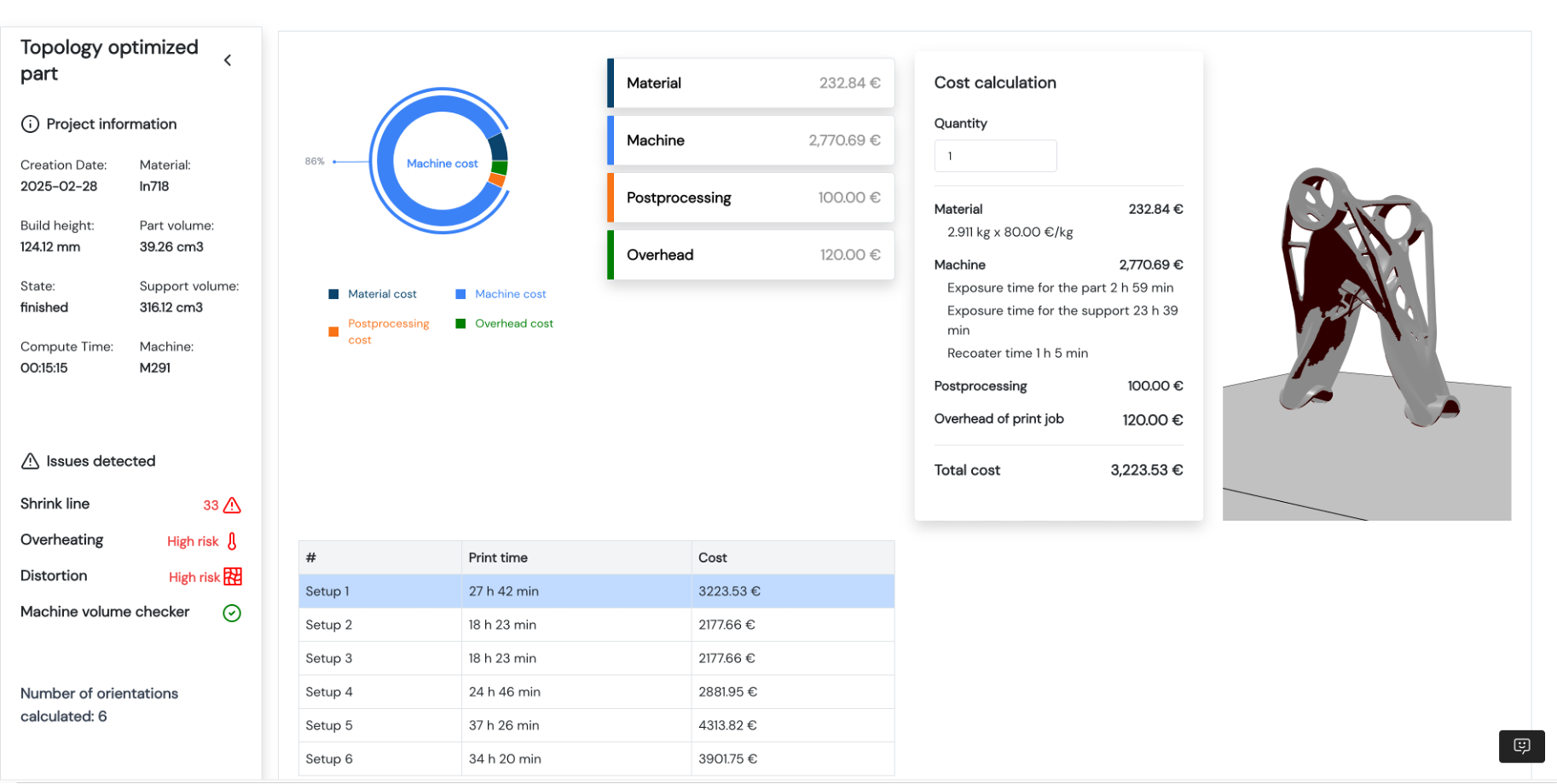

Printability Checker

Quickly assess risks like overheating, shrink lines, and distortion in your designs to ensure they are optimized for additive manufacturing.

Automated quotation

Accurately estimate production costs and generate quotes with ease, helping you save time and stay price-competitive.

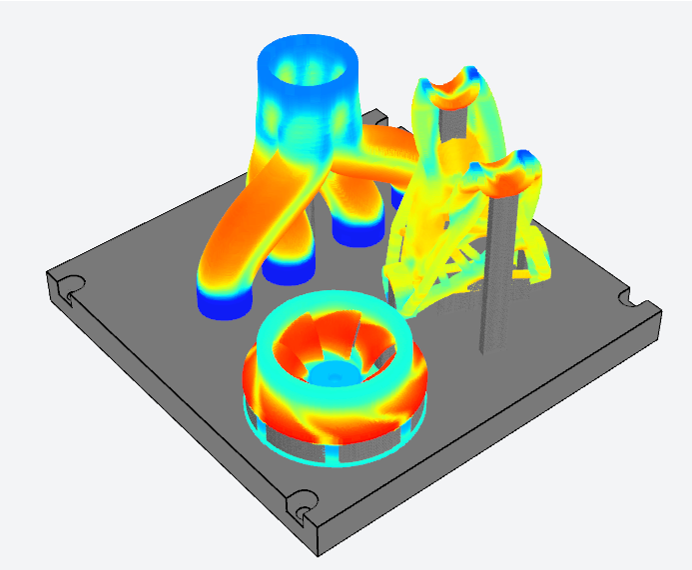

Automatic Build Preparation

Automatically orient, nest and generate supports for your parts using fast AI-based thermal physics predictions to optimize your build setup.

Exposure strategy optimizer

Predict and correct thermal issues to improve print quality and prevent defects, ensuring faster, high-quality production.

Why choose AMAIZE 2.0?

AMAIZE streamlines and optimizes metal 3D printing workflows through AI-driven automation and intelligent predictions. Instead of relying on manual trial-and-error processes, AMAIZE provides precise, data-backed insights to ensure higher quality prints, reduced failures, and cost-efficient production.

Its key advantage lies in efficiency and reliability—by identifying potential print issues early and optimizing build setups automatically, users can save valuable time and resources. For businesses aiming to scale additive manufacturing while maintaining high precision and profitability, AMAIZE is an indispensable tool.

Our Ecosystem: