The future of additive manufacturing is AMAIZE'ing!

AMAIZE makes printing additive manufacturing metal parts fast and cost-effective, predicting printing errors and defects and suggesting actionable correction strategies.

How does AMAIZE work?

AMAIZE offers a flexible, seamlessly integrated workflow with machine OEMs which improves part production and significantly reduces trial & error when developing print-ready parts.

.

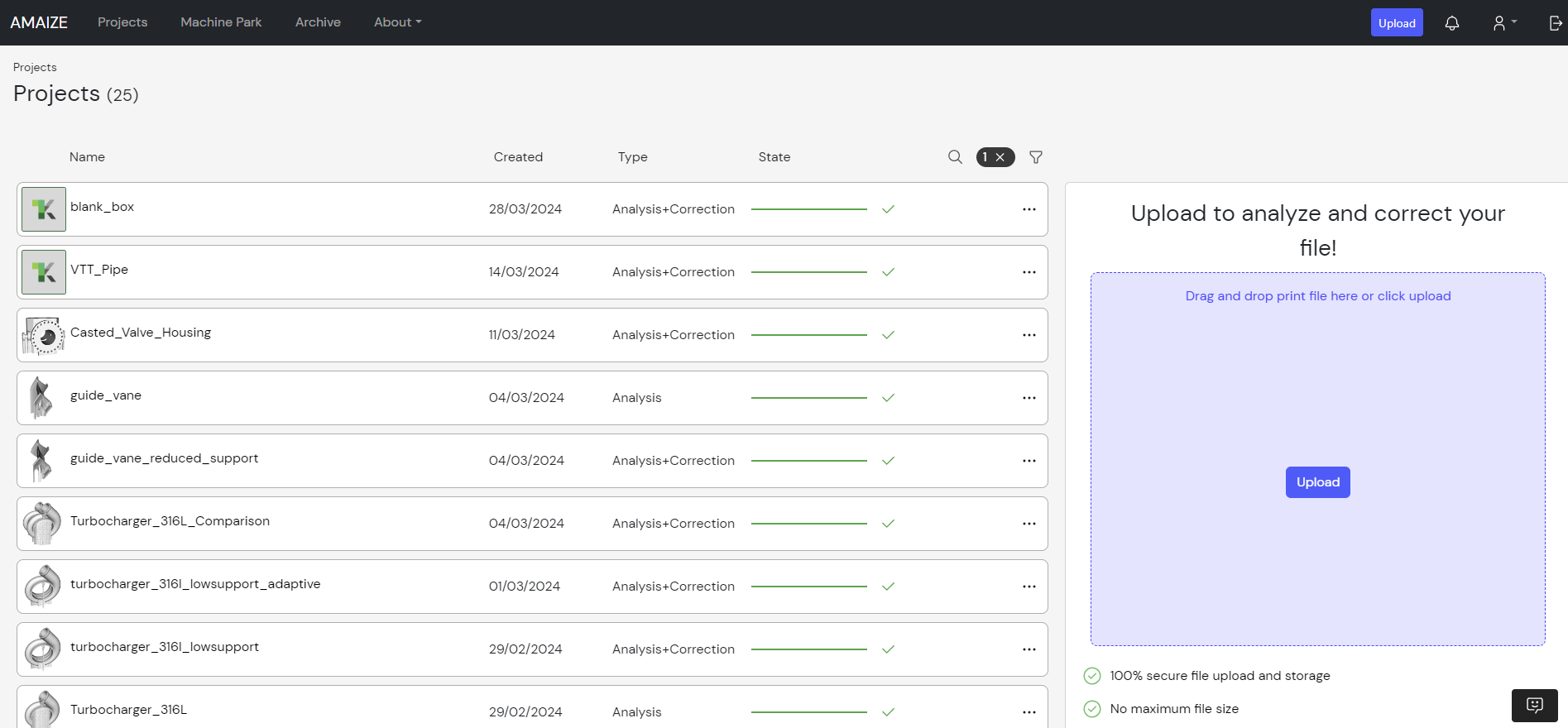

Import print file

- Import any OEM task file in AMAIZE dashboard.

- Select the material

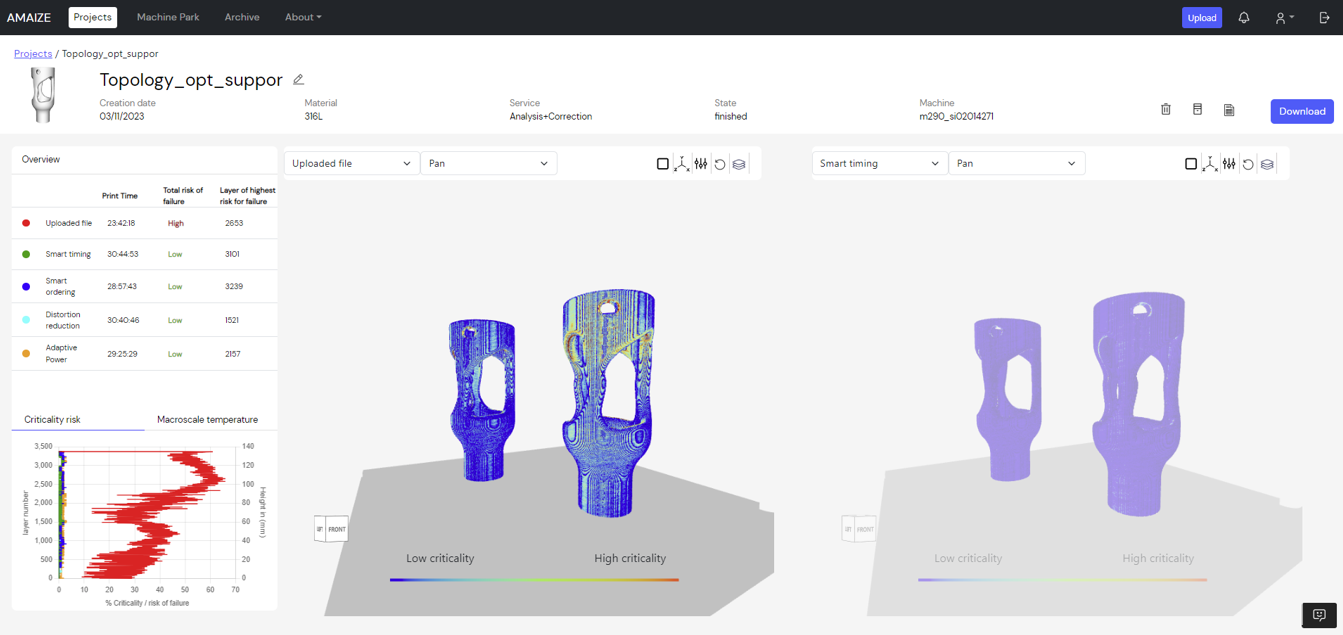

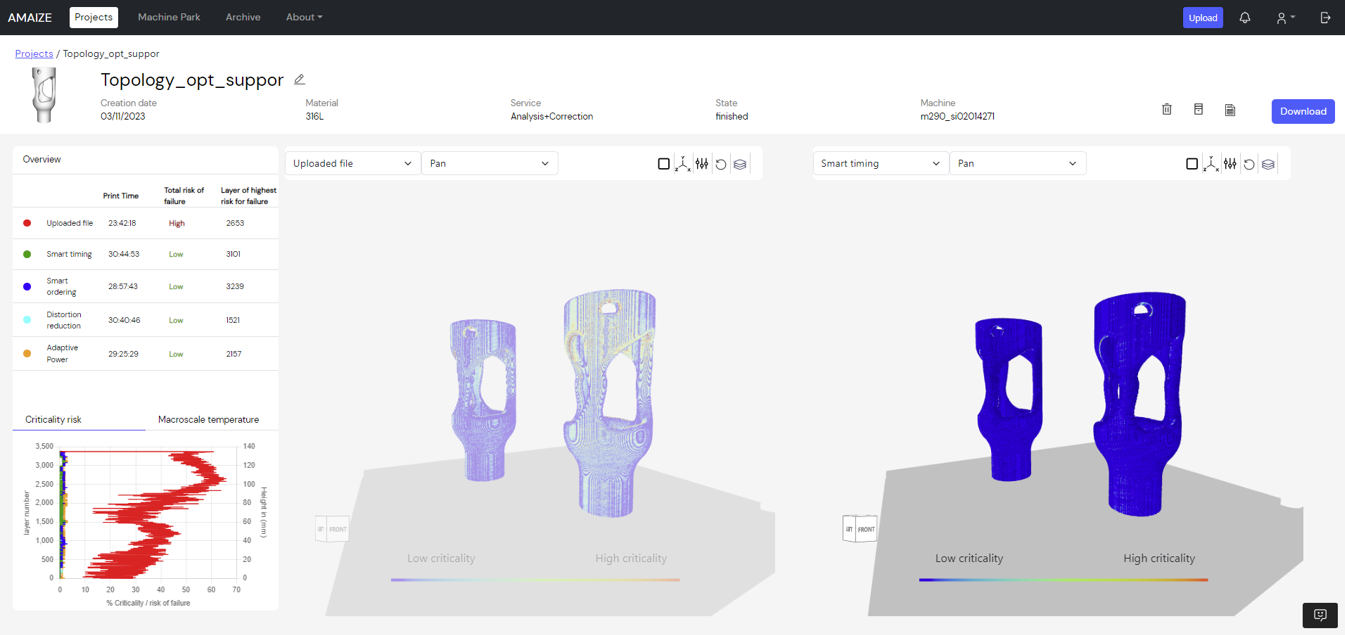

AI-Powered Analysis

- AMAIZE analyzes the scan strategy to predict process anomalies, leading to potential defects

- AMAIZE tags the problematic vectors and regions, for subsequent correction and optimization.

Apply Corrections

- Choose among the multiple correction strategies available

- Control your correction constraints

- Automatically correct the scan strategy and problematic regions

- Compare the results of the correction strategies and select the one that works better for you

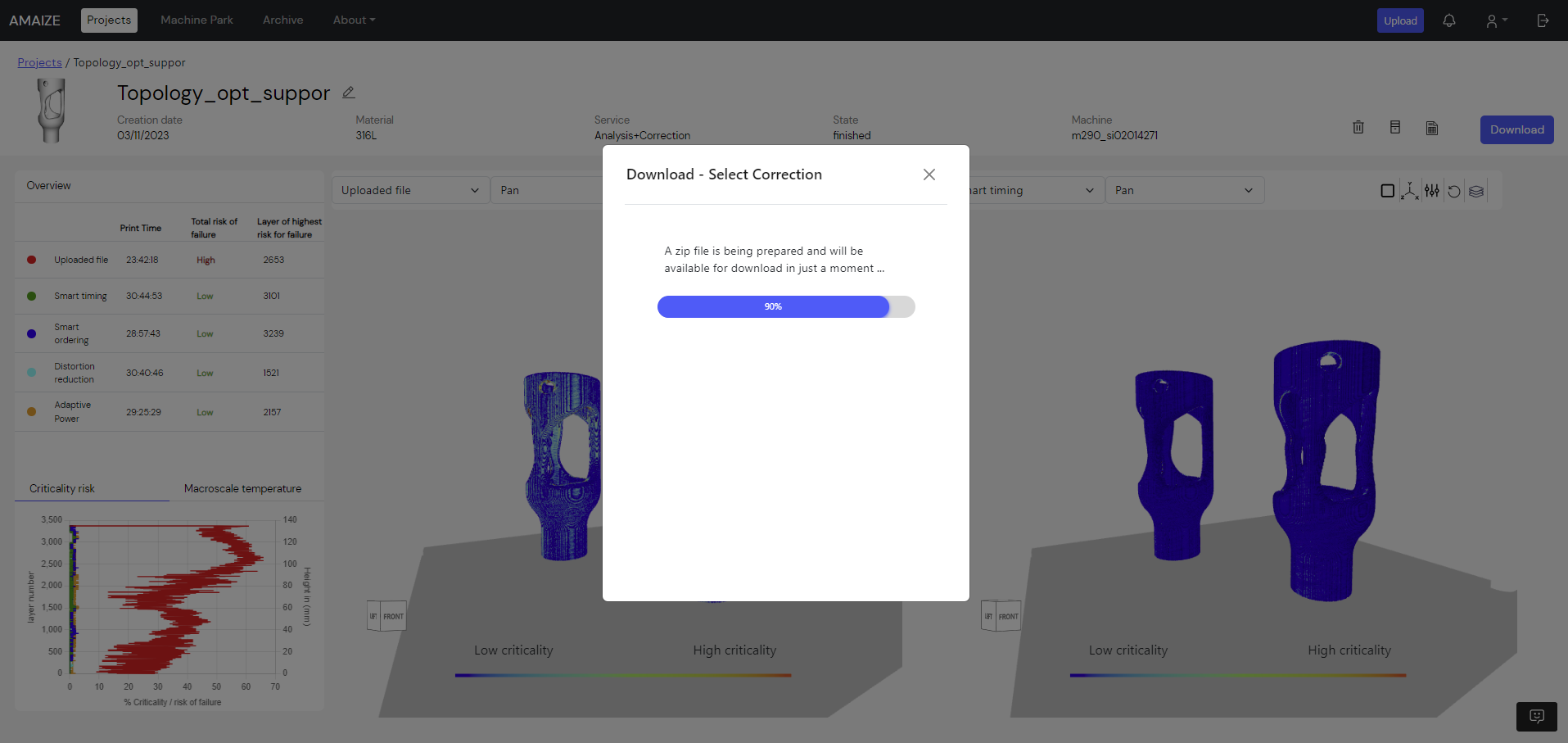

Export & Print

- Export the build file in machine format

- Upload the new correction strategy directly to the machine

- Print the part, first-time-right

Accuracy

< 1 % deviation between prediction and print

Speed

x 10^8 faster than traditional FE method

Simplicity

5 mins training, also runs on your existing IT infrastructure

Automation

Direct and seamless OEM integration

What can AMAIZE do for you?

-

C-Level

-

AM Managers

-

AM Engineers

Maximize operational excellence, optimize profit margins

- Cut Additive Manufacturing Expenses without Compromising on Quality

- Boost Overall Equipment Effectiveness (OEE) for Superior Conversion Rates

- Sharpen Order-to-Delivery Time (ODT) to Multiply Your Profit Margins

Maximize ROI, Optimize Capacity, Empower Teams

- Achieve Operational Excellence with up to 20% Efficiency Gain and 15% Increased Capacity

- First-Time-Right Manufacturing: Zero Scrap, 100% Material Utilization

- Elevate Team Efficiency by 30% While Lowering TCO by 20% with Scalable SaaS Solutions

AI as Your Co-Pilot, Not Your Replacement

-

Augment Your Expertise: Eliminate trial-and-error, letting you focus on design innovation and problem-solving

- Real-Time Collaboration: Receive instant, AI-powered feedback to refine your work, not replace it

-

Quote with Confidence: De-risk your quotations and elevate your role as the go-to expert on project feasibility and cost-efficiency

Got questions?

Does AMAIZE train on my data?

No, AMAIZE is pre-trained by 1000 Kelvin for every material model available.

Does AMAIZE dynamically modify print parameters?

No, AMAIZE predicts print issues and optimized the print file upfront.

How does AMAIZE connect to 3D printing systems?

We work together with machine OEMs and integrate through their API. The integration is then tested extensively before going into production.

Can I choose which parameters to lock and which ones to change?

Yes, AMAIZE is effectively an AI co-pilot and the user is always in control of what happens.

How long does a prediction and correction require?

Depending on the build job size, it can take between few minutes to few hours.

Can I qualify parts printed with AMAIZE correction?

Yes, you can qualify parts printed using AMAIZE by simply locking the parameters specified by your qualification requirements.

Do I need to install any hardware?

No, AMAIZE is a Software-as-a-Service. All you need is a log in.

What is the ROI one can expect after integrating your software?

How does the software integrate into existing workflows?

What is your data security and compliance policy?

AMAIZE is hosted on AWS and can be deployed on both public and private clouds. We're in the process of obtaining ISO27001 certification and offer multiple encryption levels. We are ITAR-compliant with GovCloud options for U.S. entities

How does the software contribute to first-time-right manufacturing?

How does the software make engineers more efficient without replacing them?

Perform multiple digital iterations in minutes, avoid print failures, and significantly reduce support structures. This empowers engineers to innovate in Design for Additive Manufacturing (DfAM) and lower costs