Check out our webinars, case studies and blogs

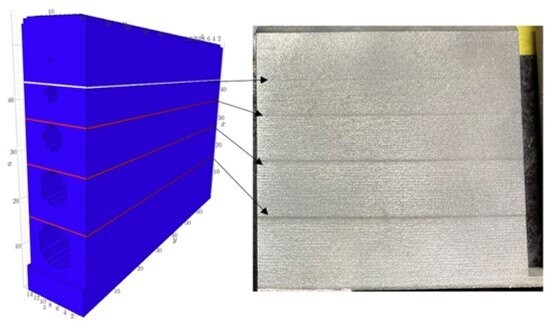

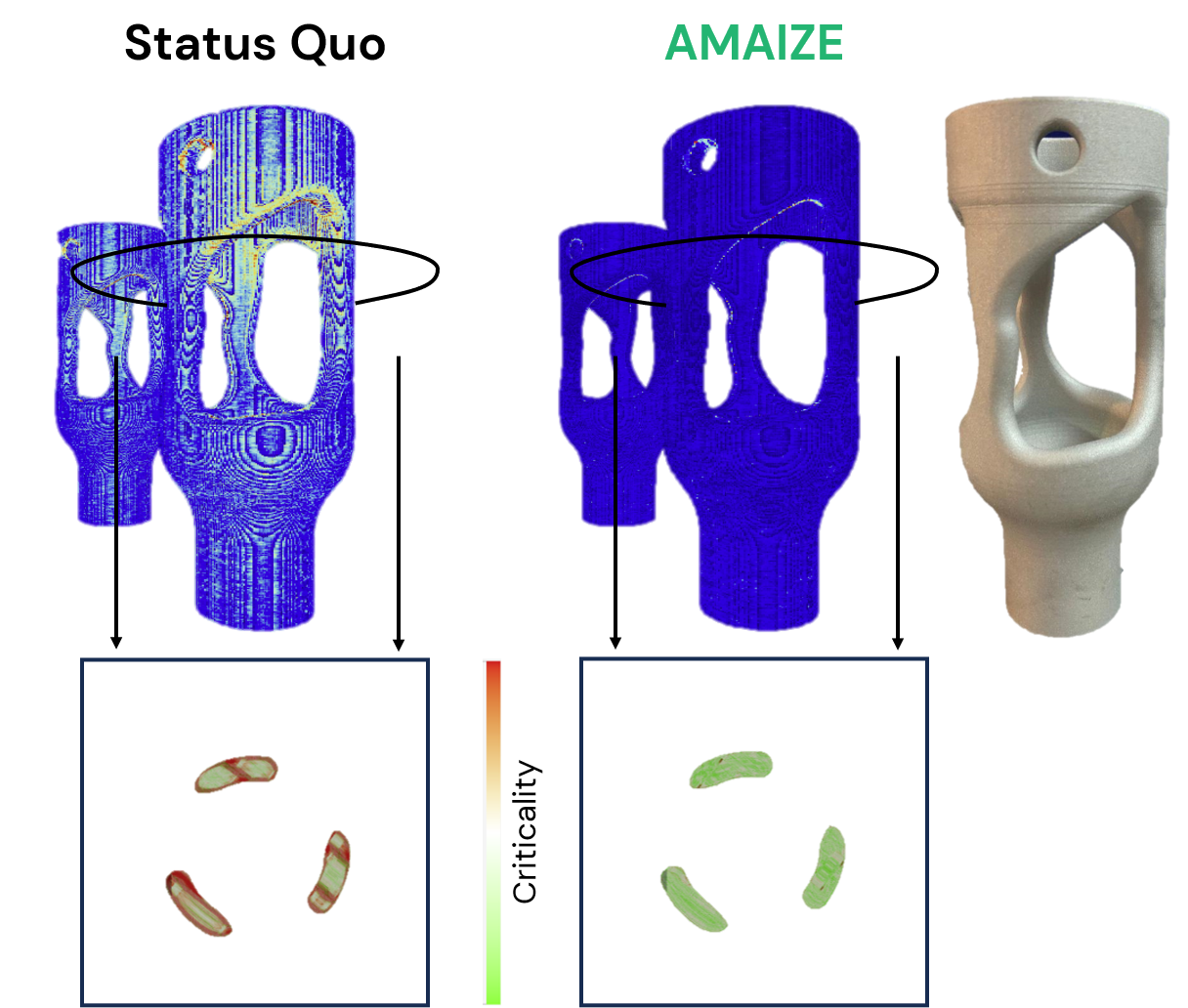

AMAIZE AI-enabled shrink lines prediction

Shrink lines occurr due to sudden changes in local temperature or stiffness, leading to dangerous stress initiations. AMAIZE predicts precisely where shrink lines form, in just few seconds.

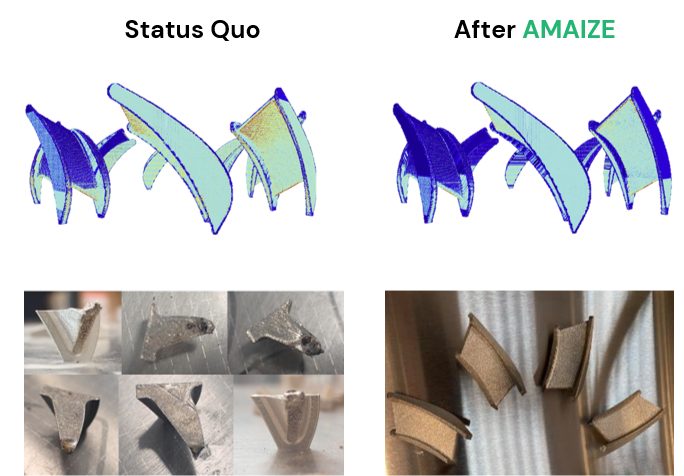

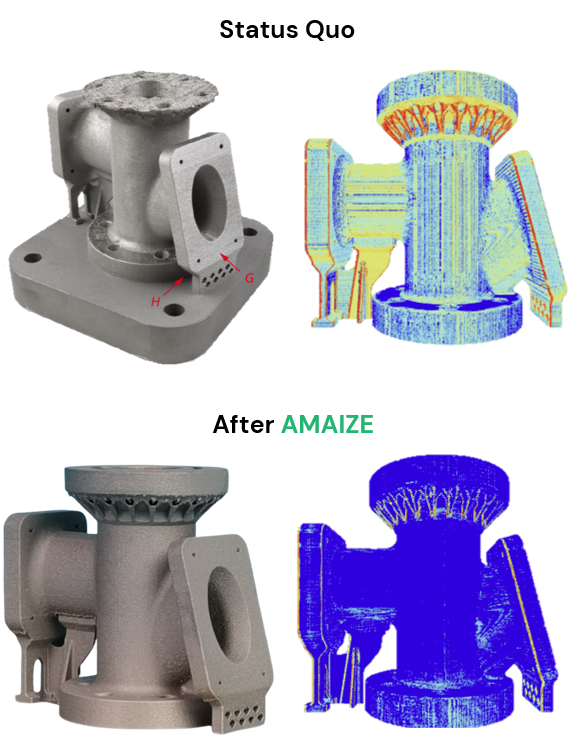

No expertise required, first-time-right on complex manifold

Using our end-to-end solution to automatically generate support structure and optimize the recipe to achieve first time right and save 90% supports with a faster print and lead time by eliminating postprocessing together with our customers FKM Sintertechnik GmbH and Chesco GmbH.

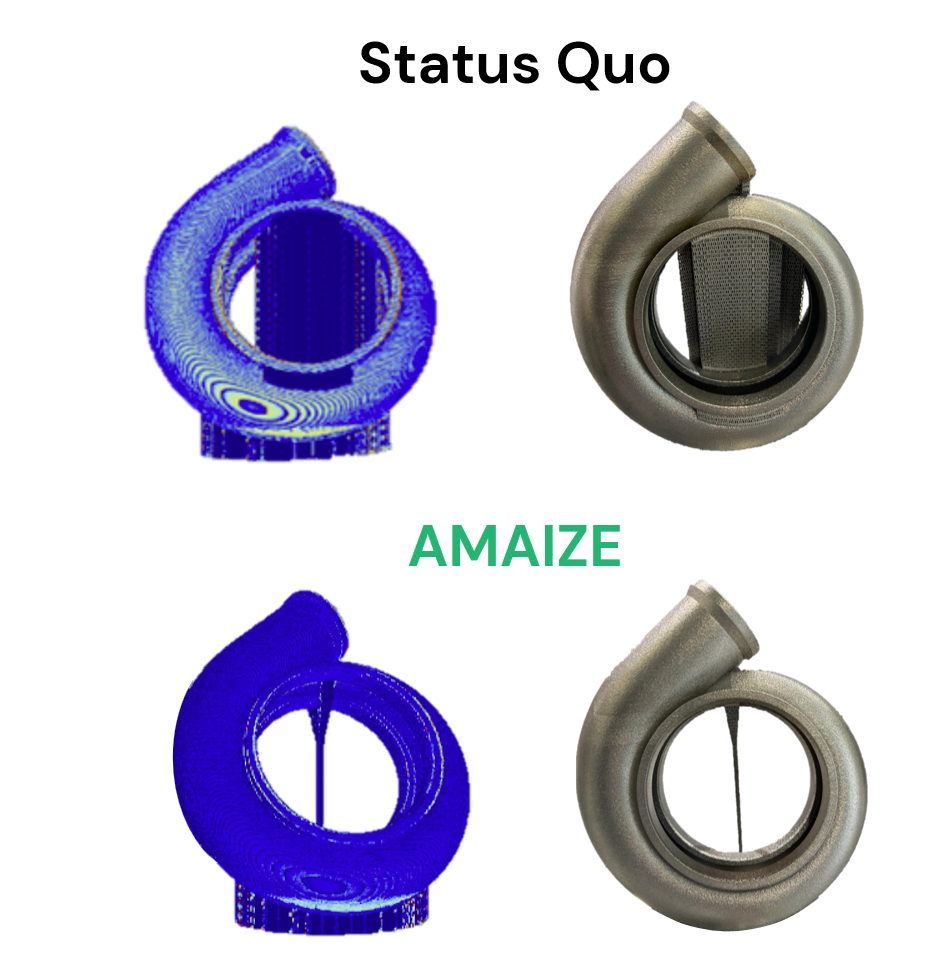

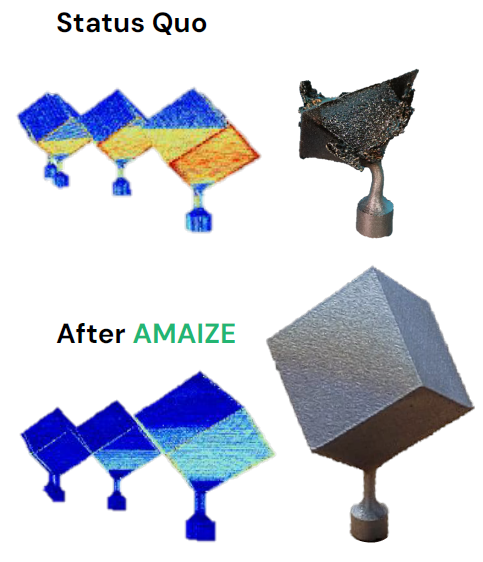

Improve thermal management - reduce cracking

Discover how AMAIZE improves thermal management to minimize the thermal gradients in the part.

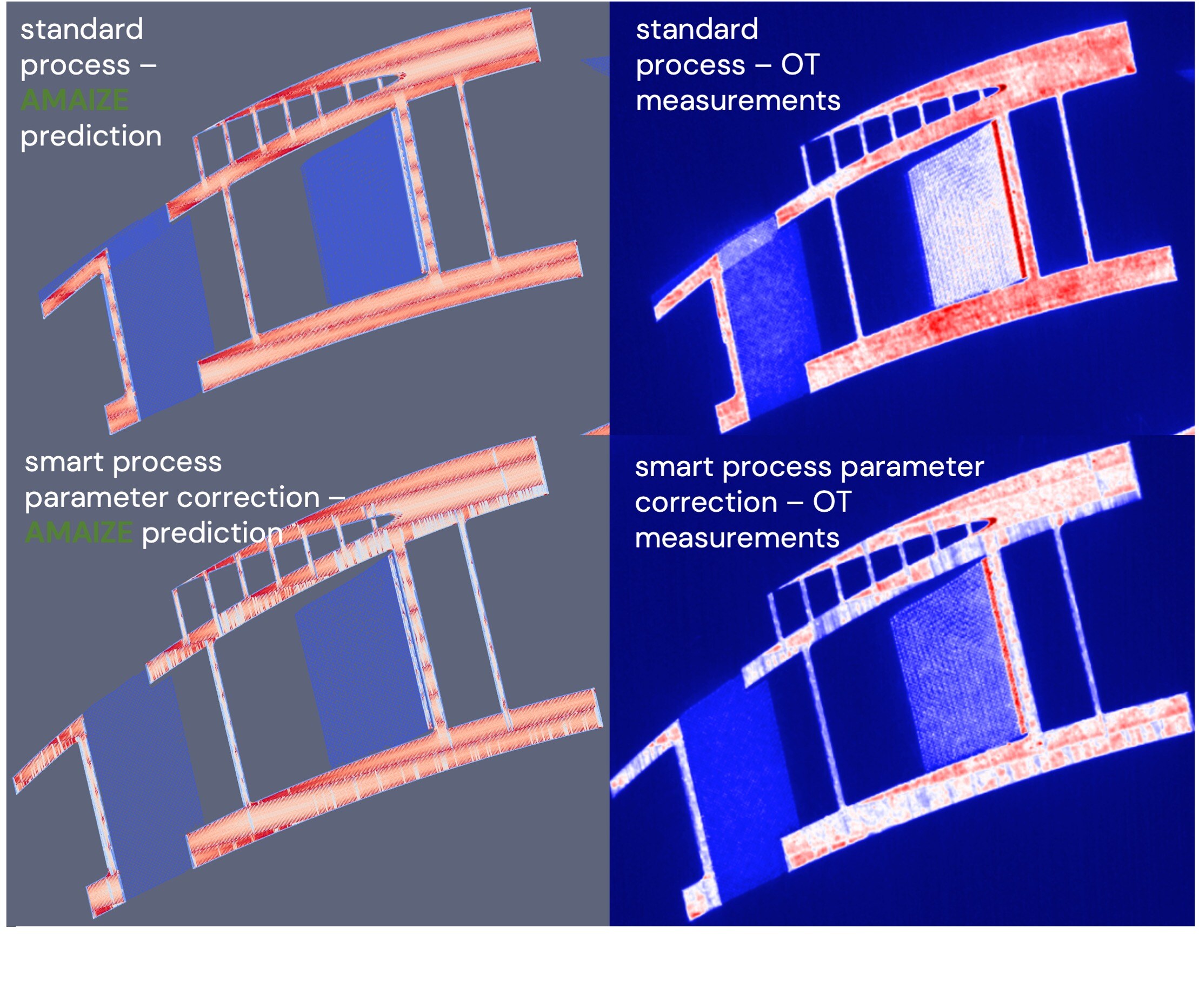

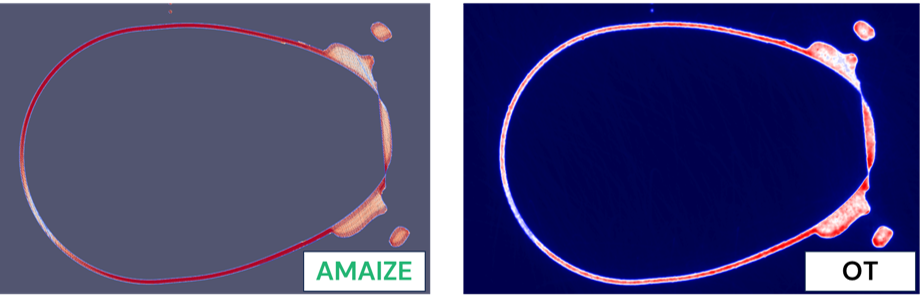

AMAIZE physics-based AI, validation with Optical Tomography (OT)

Process induced defects observed in LPBF include hotspots, which are a sign of local overheating leading to non-homogeneous microstructures. In this study, we Optical Tomography (OT) to capture the layer based thermal emissivity. AMAIZE prediction, based on physics informed AI, accurately predicted layer thermal history, temperature and hot spots measured by OT. These validated results pave the way for faster qualification of components.

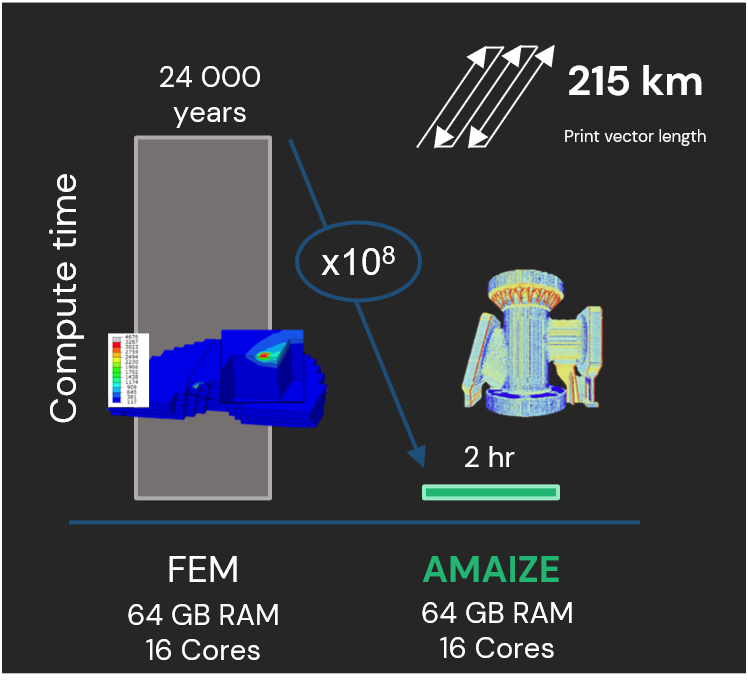

Bring unprecedented speed and resolution to your AM process

The key to being able to analyse complex parts with unprecedented resolution and providing optimized corrections is the compute speed. To better understand the enabling effect of compute speed, we compred a part comprising of 215km of print vectors analysed with AMAIZE vs. Finite Element Method (FEM). Download the case study to check out the results.

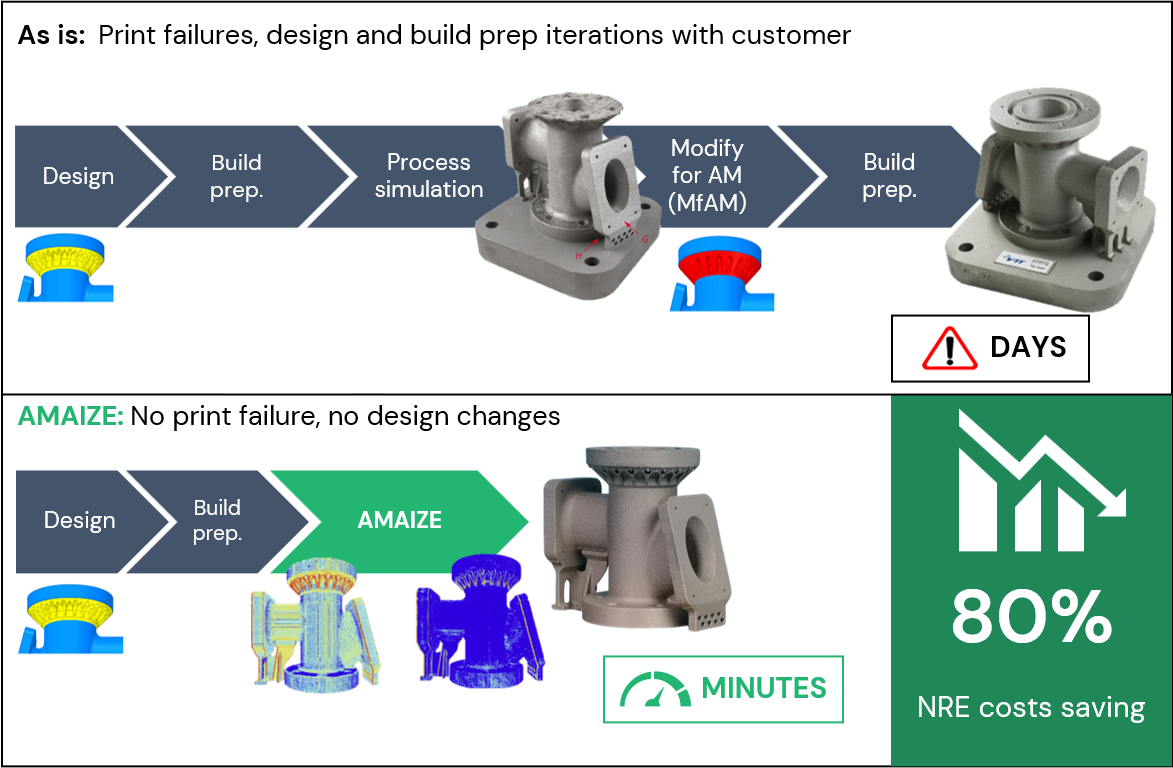

Cut your Non-Recurring Engineering (NRE)

Contract manufacturing companies using Laser Powder Bed Fusion (LPBF) systems spend millions of dollars yearly on Non-Recurring Engineering (NRE) to manufacture high quality products, leading to higher operational cost and longer delivery time. In this study, we demonstrate how using AMAIZE, it is possible to cut by up to 80% your NRE cost and enhance your on-time delivery rate (ODT).

Reduce lead time

Discover how AMAIZE accelerates engineering during functional prototyping and post-processing, leading to 80% lead time reduction

Reducing cost per part

Reduction of cost per part (CPP) by reducing support structures and eliminating post processing

Streamline engineering

Thermal Problem-Solving with AMAIZE, correcting the print file, homogenizing and reducing the overall temperature in the part

Increase yield

Thermal Problem-Solving with AMAIZE's Autonomous Advanced Prediction and Correction Technology.

VTT Pipe Structure - before and after AMAIZE

Get our free whitepaper on how AMAIZE unlocked the possibility of printing this pipe structure first time right, vs. several trial & error iterations with traditional methods.

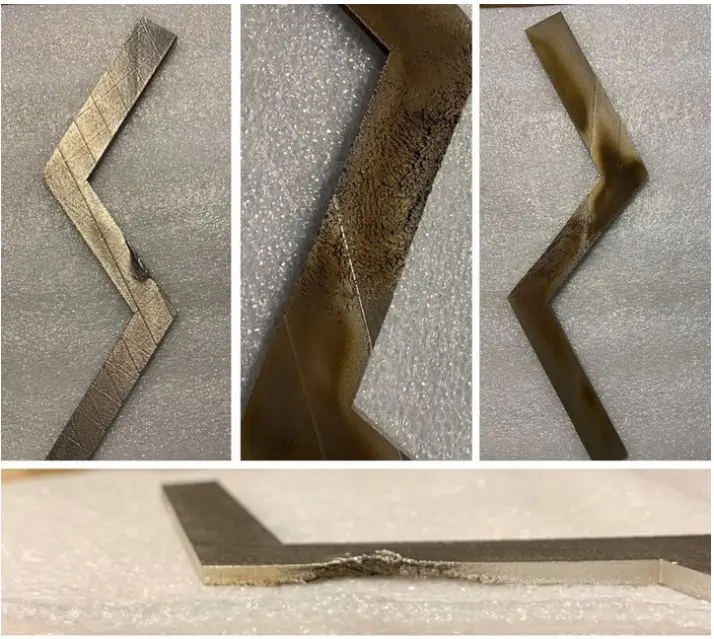

ZIG-ZAG Structure - A case study

Get our free use case on how AMAIZE was able to predict and correct the failure in this zig-zag structure

Beyond buzz - How AI will concretely help you scale your (LPBF) operations

September 27, 2023 5:00 PM - 6:00 PM UTC

AMAIZE: Replacing Expensive Trial-and-Error and Time-Consuming FEM with AI-Enabled First-Time Success

May 16, 2023 4:00 PM - 5:00 PM CET